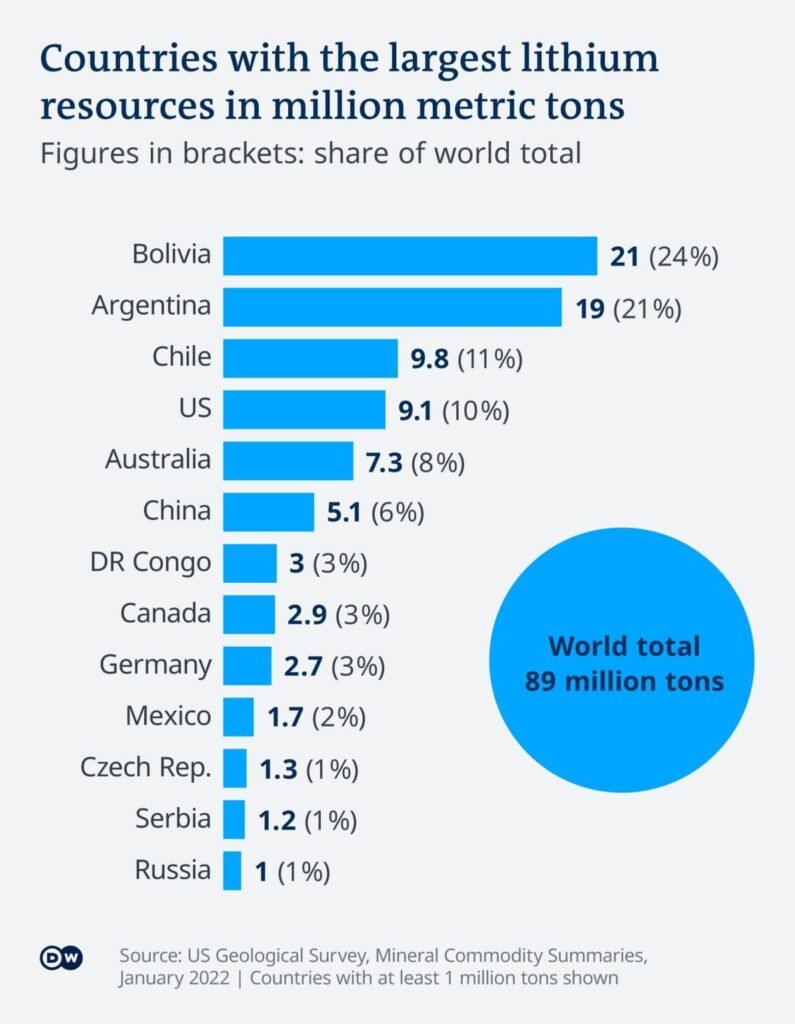

Lithium, also known as “white gold” due to its market value and silver hue, is abundant in the earth’s crust yet is extremely finely scattered. The amount of light metal in the world’s oceans is estimated to be over 200 billion tonnes by researchers. Deposits in rocks and salt lakes on land are estimated to total 98 million metric tonnes, with 26 million of them economically mineable in the coming decades.

An electric automobile does not require a lot of lithium to run. A 300-kilogram (50-kWh) mid-sized model battery comprises just about eight kilogrammes of light metal.

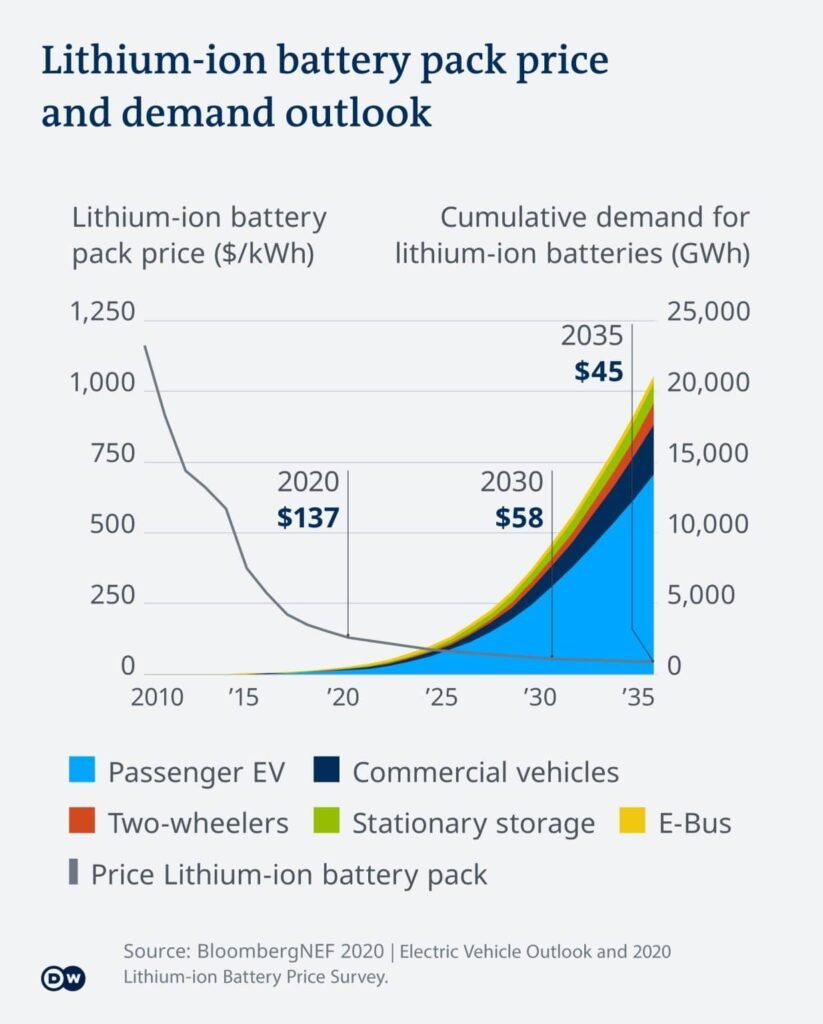

Yet, as the electric vehicle sector accelerates faster than many predicted, demand for the element required for battery manufacturing is increasing. That is problematic, given that lithium extraction operations typically take several years to build and can be contentious.

Several proposals have been greeted with opposition because open-pit miners ruin landscapes and threaten water supplies.

According to the German Mineral Resources Agency, 43,000 metric tonnes of lithium were extracted worldwide in 2016. (DERA). By 2022, that figure had tripled to 130,000 metric tonnes, and by 2030, the amount mined may more than quadruple again, according to the authority.

According to DERA lithium expert Michael Schmidt, the question now is how to extract enough battery-grade lithium to meet demand in a sustainable manner. “There are dynamics at work that I haven’t seen in 12 years of resource management.”

In 2022, Australia’s open-pit mines supplied 47% of global lithium demand, South America’s salt lakes supplied 35%, China supplied 15%, and Zimbabwe, Portugal, and North America supplied less than 1% apiece.

Lithium Derived From Salt Lakes

The world’s greatest lithium reserves are discovered in Bolivia, Argentina, and Chile’s subsurface salt lakes, which are estimated to have 42 million tonnes of metal. The US Geological Survey estimates that around 45,000 tonnes will be mined there in 2022.

The salty brine is pumped from the depths into massive basins, where it evaporates in the sun in as little as two years. The concentrated brine is subsequently filtered and chemically extracted lithium carbonate, a fundamental ingredient used in battery manufacture. According to a Swedish Environmental Research Institute study, CO2 emissions from this extraction technology are relatively modest, ranging from 50 to 100 kg of CO2 for a car battery (50 kWh).

Unfortunately, this method of lithium extraction can cause issues with drinking water. Pumping brine can cause groundwater levels to drop, and river courses and wetlands to dry up. There is a scarcity of agricultural water in some areas.

Lithium Derived From Solid Rock

The majority of lithium is currently produced in open pits in Australia by mining solid rock (pegmatites). According to preliminary projections, approximately 61,000 tonnes will be extracted in 2022. Australia’s lithium reserves are estimated to be 6.2 million tonnes.

Drilling and blasting are used to extract lithium ore. In a factory, the lumps are crushed, and the lithium is extracted from the overburden using chemical and metallurgical procedures.

The lithium is then shipped to China, where it is purified and turned into battery cells. According to a study conducted by Argonnen National Laboratory, a federally supported research and development institution in the United States, lithium extraction from ores is approximately six times more energy-intensive than extraction from salt lakes, and thus more damaging to the environment.

According to a US study, extracting lithium from ores uses roughly twice as much fresh water as removing it from salt lakes. The enormous open-pit mine at Greenbushes is located in a particularly humid region in southwestern Australia. Water use is thus less of an issue in such case.

Water supply is a significant challenge in the dry Pilbara mining region of northern Australia.

Geothermal Energy Lithium

Lithium costs are extremely high, and numerous efforts are now being encouraged in Europe in order to supply the fast expanding demand for automobile batteries. Mining projects in Finland, Ireland, Germany, the Czech Republic, Austria, Serbia, Spain, and Portugal are included.

Lithium will be recovered from solid rock reserves through open-pit and underground mines, similar to the Australian technique. All of the projects are thought to be profitable.

Separately, programmes to extract lithium from thermal water are being developed in the United Kingdom, France, and Germany. Geothermal facilities extract water from depths of up to 5,000 metres at temperatures of up to 200 degrees Celsius and use the heat to generate electricity and heat distribution networks. The cooled water is then injected underground.

In some circumstances, lithium can be removed straight from the extracted water using advanced lithium extraction (DLE) technology. Such extraction plants do not now exist on a significant industrial basis.

Vulcan Energy, a German-Australian business, intends to begin commercial extraction in the Upper Rhine Valley of southern Germany in 2025, producing 4,000 tonnes of lithium in the first phase. Vulcan’s mining area is thought to contain three million tonnes of light metal.

This process’s lesser environmental effect is highlighted as a benefit. Because the energy used in the extraction process is derived from deep geothermal energy, it is climate-neutral, and this lithium no longer needs to be transported across oceans for European battery production.

Lithium Is Being Saved Through Recycling And Sales

Lithium might be produced as a byproduct in desalination plants in a few decades, filling supply shortfalls. This extraction process is currently not considered profitable.

Lithium extraction from outdated batteries will also be essential in the future. Recycling, according to DERA models, will cover a portion of the lithium demand in the 2030s.

However, the available battery volumes are still insufficient for commercial extraction, and lithium batteries from e-cars are deployed in huge battery storage systems, such as solar parks.

“But, if the volume of used batteries increases, we will see more lithium through recycling. This is particularly critical for long-term use,” stated Michael Schmidt.

Furthermore, raw materials experts such as Schmidt and environmental organisations advocate for the most efficient use of lithium and batteries. They argue that creating huge electric vehicles with the largest batteries available is not a sustainable use of resources.

Instead, lighter vehicles with batteries should be sold first and made available to as many people as feasible. It would also be beneficial to extend car-sharing and public transportation so that fewer individuals require their own e-car, resulting in a lower demand for the so-called white gold.